Before we delve into the benefits of thermal imaging in industrial inspections, it’s important to understand what thermal imaging is and its fundamental principles.

What is Thermal Imaging?

Thermal imaging, also known as infrared Thermography or Thermology, is a non-invasive technology that detects and visualises heat patterns emitted by objects. Every object with a temperature above absolute zero emits infrared radiation, which thermal cameras capture and translate into visible images called Thermograms.

Fundamental Principles

Non-contact measurement: Thermal imaging allows for temperature measurement without physical contact, making it safe and efficient for inspecting various industrial equipment.

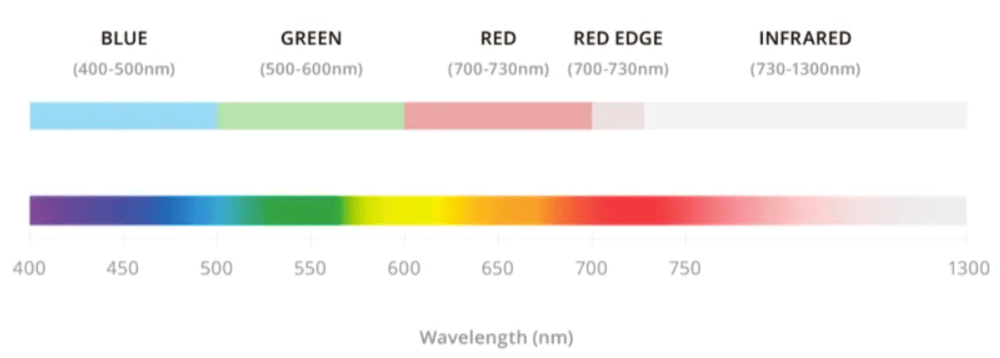

Infrared radiation detection: Thermal cameras detect infrared radiation emitted by objects, converting it into a visible temperature distribution map.

Real-time visualisation: The technology provides immediate, real-time visual representation of temperature differences across surfaces and equipment.

Advanced Thermal Imaging with DJI Mavic 3T Enterprise

At Professional Drone Imagery, we utilise the commercial grade DJI Mavic 3T (Thermal) Enterprise drone for our thermal imaging needs. This advanced drone offers a range of features that enhance our industrial inspection capabilities:

High-Resolution Thermal Camera: The Mavic 3T boasts a thermal camera with a resolution of 640 x 512 pixels, providing detailed thermal images for precise analysis.

Multiple Colour Palettes: Various colour schemes are available to visualize thermal data, allowing for customised viewing based on specific inspection requirements.

Isotherm Functionality: This feature can be toggled on or off to highlight specific temperature ranges, making it easier to identify areas of concern.

Point and Area Temperature Measurement: The drone can measure temperatures at specific points or within defined areas, offering versatile temperature analysis options.

High Temperature Alerts: Automated alerts can be set to notify operators when certain temperature thresholds are exceeded, enhancing safety monitoring.

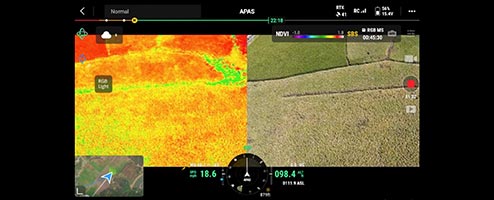

Split-Screen Zoom: With 28× continuous side-by-side zoom capability, the Mavic 3T allows for easy comparison between thermal and visual imagery.

Dual Gain Modes: The thermal camera operates in two temperature ranges (-20°C to 150°C and 0°C to 500°C), accommodating a wide spectrum of industrial applications.

Now, let’s explore the numerous benefits that thermal imaging brings to industrial inspections.

Early Problem Detection

One of the primary advantages of thermal imaging is its ability to identify issues before they escalate into equipment failures. By detecting temperature anomalies that often indicate underlying problems, thermal cameras can spot overheating in bearings, motors, or electrical circuits early on. This early detection allows for preventive maintenance, reducing the risk of costly, unplanned shutdowns and extending equipment lifespan.

Improved Safety

Thermal imaging significantly enhances workplace safety. By identifying potential electrical faults, mechanical issues, and fire hazards, it helps prevent accidents and ensures a safer working environment. For instance, thermal cameras can detect hotspots in storage areas that might indicate potential fire risks, allowing for timely intervention.

Energy Efficiency

In an era where reducing carbon footprints is paramount, thermal imaging plays a crucial role in optimizing energy consumption. Equipment operating outside its optimal temperature range often consumes more energy. By pinpointing these inefficiencies, thermal imaging encourages prompt corrective action, leading to energy savings and reduced operational costs.

Non-Disruptive Inspections

One of the most significant benefits of thermal imaging is its non-invasive nature. Inspections can be carried out quickly without halting operations, saving valuable production time. This aspect is particularly beneficial in industries where downtime can result in substantial financial losses.

Versatility Across Industries

Thermal imaging finds applications in a wide range of industrial sectors. From electrical systems and mechanical equipment to building diagnostics and even veterinary applications, its versatility makes it an invaluable tool. Industries such as manufacturing, power generation, and facility management all benefit from the insights provided by thermal imaging inspections.

Cost-Effective Maintenance

By enabling a proactive approach to maintenance, thermal imaging helps reduce overall maintenance costs. It allows for the identification of specific components that require attention, eliminating the need for unnecessary replacements and reducing labor costs associated with reactive maintenance.

Compliance and Insurance Benefits

Many insurance companies now recognize the value of thermal imaging inspections. Some even require these inspections as part of their risk assessment process. Regular thermal imaging surveys can lead to reduced insurance premiums and demonstrate a commitment to safety and equipment reliability.

Precision in Problem Identification

Thermal imaging cameras provide detailed temperature distribution maps, allowing technicians to precisely locate and assess the severity of issues. This precision enables more accurate diagnoses and more effective repair strategies.

Thermal imaging has become an essential tool in industrial inspections, offering a wide array of benefits from early problem detection to energy efficiency and cost savings. As industries continue to seek ways to improve reliability, safety, and efficiency, the role of thermal imaging in predictive maintenance and condition monitoring will only grow in importance.